Shop

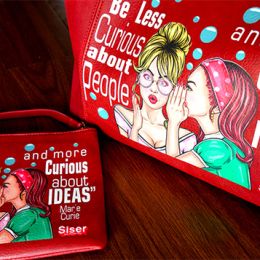

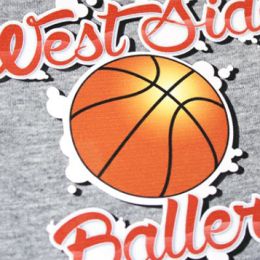

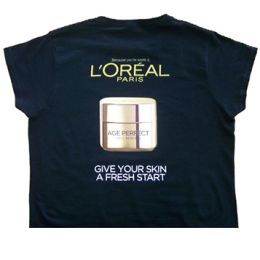

Siser Digital

Conect Enterprises are an Authorised Distributor for Siser®

Click here to watch "A guide to Print and Cut materials from Siser"

Items 1-12 of 13

SISER EASY COLOR CRAFT PACK (5sht)

Special Price

$21.95

Regular Price

$28.88

SISER S-PRINT

Starting at

$13.95

Starting at

$0.00

SISER SPARKLEPRINT

Starting at

$18.87

Starting at

$0.00

COLORPRINT EXTRA

Starting at

$18.87

Starting at

$0.00

COLORPRINT PU MATT

Starting at

$12.00

Starting at

$0.00

COLORPRINT PU GLOSS WHITE

Starting at

$12.00

Starting at

$0.00

CONECT COLORPRINT PU EXTRA GLOSS

Starting at

$10.00

Starting at

$0.00

COLORPRINT

Starting at

$30.02

Starting at

$0.00

SOFT PRINT COLOR VIVID

Starting at

$12.00

Starting at

$0.00

SOFT PRINT COLOR MATT

Starting at

$12.00

Starting at

$0.00

SISER EASY SUBLI

Starting at

$3.20

Starting at

$0.00

TTD SISER EASY APP TAPE

Starting at

$11.45

Starting at

$0.00

Shopping Options

- Price

-

Product Comparison

Can't make up your mind?

You can now select up to 4 products to do a product comparison. Do a comparison now